Above All - Ohio | Services | Infrared Applications | Mechanical

| Obliques | Verticals | Video | Thermography | Aerial Lift | Construction | Architectural | Graphics |

| Infrared | Roofing | Wildlife | Mechanical | Electrical | Building | R & D | Analysis & Reporting |

|

Regularly scheduled thermal infrared inspections are a very important part of any preventative maintenance ("PM"), predictive maintenance ("PdM"), or condition-based maintenance ("CBM") plan. Infrared inspections are 100% passive and make no contact with the subjects of the inspection. Mechanical infrared inspections should ideally be carried out under normal operating conditions and during normal production hours. Our inspections do not cause any disruptions to your process and do not require expensive downtime. Our images will work for you. Our images will show you unseen existing problems and signs of future problems so you can take care of them during your next scheduled downtime, not when the components unexpectedly fail and force downtime. By the way, Above All - Ohio is available 24/7 for inspections so we can accommodate your schedule - no matter what "normal production hours" means for your company! |

| An Infrared Case Study: Mechanical Inspection by Above All - Ohio | ||

|

||

|

Background information and findings:

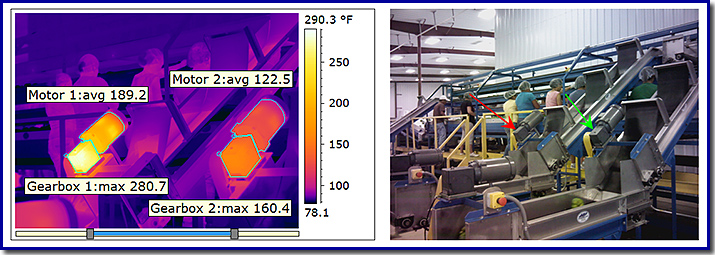

A thermal scan of a

brand new production line was ordered.

Our inspection of the running line quickly revealed a serious problem with one of the conveyors. The gearbox driving it was dangerously hot and was causing its attached electric motor to overheat as well. |

Action taken:

We reported the problem to the maintenance manager immediately. The conveyor

was promptly shut down and the gearbox was guarded due to it's high surface

temperature.

Later, Above All - Ohio generated a detailed report which included both of the images shown above (infrared and visible images are acquired simultaneously during our inspections). The hot gearbox ("Gearbox 1", red arrow) was shown in relation to an identical one which was operating at normal temperatures ("Gearbox 2", green arrow). The report was e-mailed to the equipment manufacturer within the hour so they could help determine the cause of the overheating. |

Conclusions:

As a direct result of Above All - Ohio's

infrared survey, a dangerously hot gearbox was identified and replaced before

anyone in the plant was injured by coming into contact with it.

Both the plant personnel and the equipment manufacturer were able to clearly see the problem and take immediate corrective action before the component failed, thereby avoiding unplanned and expensive downtime. Because the problem was detected early, our findings also saved the manufacturer the expense of replacing a motor and gearbox assembly under warranty. |

|

Contact us today to add infrared inspections to your

preventative maintenance (PM) or condition-based maintenance (CBM) plan!

We look forward to showcasing YOUR infrared success story here! |

||

| Sample Images for Infrared Mechanical Applications |

|

|

|

Hydraulic oil tank and associated pump and hoses |

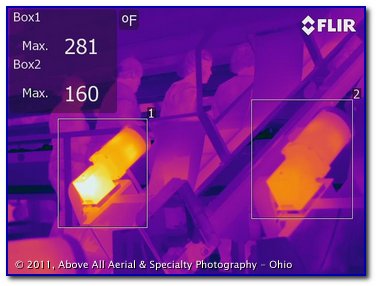

A hot gearbox and motor with an identical setup for comparison |

|

|

|

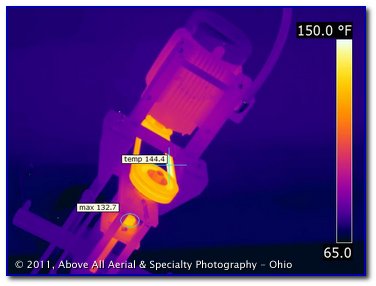

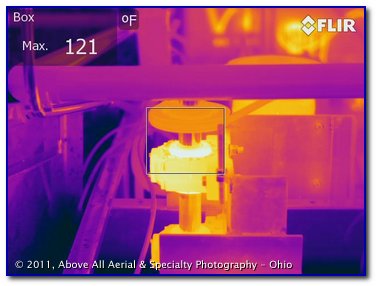

Image showing operating temperatures of a belt and a bearing |

A close-up infrared view of a bearing at operating temperature |

|

|

|

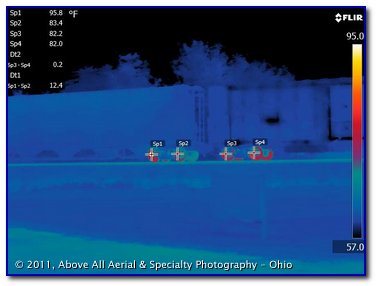

This infrared image of a passing freight train reveals that one of the four wheel bearings visible is ~12° F warmer than the others. This may indicate that the bearing is wearing out or it may simply indicate a lack of lubrication. |

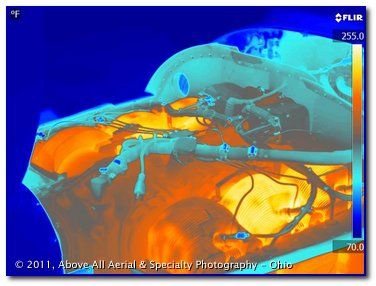

This infrared image of a warmed up 6-cylinder airplane engine reveals that the middle cylinder on each side of the engine is warmer than the others (as may be expected...). |

Above All Aerial & Specialty Photography - OhioOur images will work for you.℠ |